Material: Aluminium with low content of copper

IP: rating IP66

Ambient temperature range: -50°C to +55°C

Approvals: INERIS 00ATEX0023X (standard) / INERIS 01ATEX0059 (battery pack) CoC TR CU 012/2011: n° B.01067 (marking upon request, ordering code to be required)

Marking:

Standard

II 2 GD Ex d IIB+H2 T6 Gb Ex tb IIIC T85°C Db IP66

Battery pack

II 2 GD Ex d IIC T6 Gb Ex tb IIIC T85°C Db IP66

Gaskets: Gasket made of Nitrile Rubber (NBR) on flat joint

Entries: Suitable for LOOP-IN LOOP-OUT UP TO 4mm2

Hardware and screws: AISI316L Stainless steel external hardware and screws

Lamps: Included

Rated operation voltage (UE): 110V/264V (standard version)

220V/240V (emergency version)

Frequency: 50/60Hz

Accessories Ceiling mounting : N° 1 brass nickel chrome plated plug + N° 1 brass nickel chrome plated

cable gland PNA type c/w set of inner seals

Pole mounting : N°1 brass nickel chrome plated cable gland PNA type c/w set of inner seals

Adjustable mounting bracket: : N°1 brass nickel chrome plated cable gland PNA type c/w set of inner seal

Archives

HIGH CURRENT CONNECTORS

*Electrical connections from 75 to 700 A

*Waterproof electrical sockets IP66/IP67

*Power outlets resistant to shocks

*GRP or metal casing.

AQ/AR SERIES GRP JUNCTION BOX

Material: GRP (Glass-fiber reinforced polyester)

IP Rating: IP66/IP67

Ambient temperature: -50°C to +60°C

Approvals: IMQ 08 ATEX 028X GOST R

Marking: II 2 GD

Ex-e IIC Gb / Ex-ia Ga IIC T(**)

Ex-tb IIIC T(**) Db IP66/67

** T6/T85°C, T5/T100°C, T4/T135°C

Standard certificate label: Made by self adhesive UV and corrosion resistant polyester, approved by INERIS Laboratory.

Accessories available on request:

*Hinges

*Drain/breather valve

*Traffolyte/Stainless steel certificate label

*Internal mounting plate

*Earth continuity plates

*Passing through earth bolt

BPG/BPGC RANGE (GRP)

The BPG range comprises 16 sizes of enclosure manufactured in glass reinforced polyester or a carbon loaded anti-static GRP (BPGC). The BPG and BPGC enclosures are suitable for use in hazardous areas, specifically ATEX and IECEx Ex ‘e’ (Zone 1 & 2), EEx ‘nA’ (Zone 2) and CSA, UL & FM (Class 1, Div 2).

Under fire test conditions the structure holds together even if the resin is depleted. The BPG range when fitted with ceramic terminals meets the requirements of IEC 331 (750°C for 3 hours) and also BS6387/1983 (950°C for 3 hours – flame only).

The BPG junction box has excellent ingress protection qualities (IP66/67 and Type 4X) due to the enclosure’s labyrinth seal system, whereby the seal is protected from the external environment. The mounting holes, although contained within the profile of the enclosure, are also designed to sit outside the seal maintaining its integrity.

The BPG range has also passed the Shell/ERA deluge test which was devised to adequately test enclosures and electrical equipment which is routinely subjected to ships decks conditions or fire deluge systems.

All external fasteners and fixings are manufactured from 316 grade stainless steel to ensure reliability. The BPG is suitable for operation in ambient temperatures ranging from -65°C to 130°C.

The BPG range is also available carbon loaded (BPGC) which helps to reduce the surface resistance of the material and consequently reduce the risk of spark from static build up.

Earthing can be accomplished by various means. External/internal earth stud which in turn can be connected to the terminal mounting rail or component mounting plate, an earth continuity plate can be fitted around the inner walls to provide continuity for cable glands and various in rail mounted earth terminals or proprietary earth bars can be fitted inside the enclosure.

The BPG range can be supplied fitted with any component approved terminal to apparatus level or can be supplied empty as component approved.

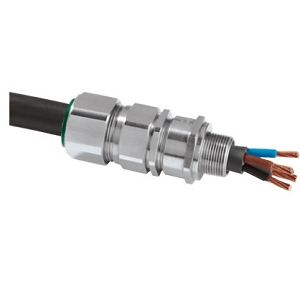

T3CDS

Ex e, Ex d, Ex nR & Ex ta | Explosive Atmosphere Cable Gland

For all types of Armoured Cables

Globally Approved, Explosive Atmosphere Cable Gland

• Fully sequential, three step installation procedure

• Reduces installation times, cost & risk

• Direct & remote installation

• Unique compensating displacement seal system (CDS)

– Metal-to-metal installation every time regardless of cable diameter

• Designed to prevent Coldflow

• Integral protected deluge seal

• Controlled outer ‘load retention’ seal

• Unique OSTG prevents overtightening

• -60˚C to +130˚C (standard), -20˚C to 200˚C (ThermEx option T3CDSHT)

• Globally marked, IECEx, ATEX, UL & cCSAus

• EMC tested

AQ/AR SERIES AISI316L JUNCTION BOX

Material: AISI316 Stainless steel

IP Rating: IP66/IP67

Temperature: -50°C to +60°C

Approvals: IMQ 08 ATEX 028X GOST R

Marking: II 2 GD

Ex-e IIC Gb / Ex-ia Ga IIC T(**)

Ex-tb IIIC T(**) Db IP66/67

** T6/T85°C, T5/T100°C, T4/T135°C

Standard certificate label: Made by self adhesive UV and corrosion resistant polyester, approved by INERIS Laboratory.

Surface treatment: Acid treatment

Accessories available upon request:

*Electropolish treatment

*Side gland plates

*Hinges

*Drain/breather valve

*Traffolyte/Stainless steel certificate label

*Internal mounting plate

*Locking facility

*Passing through earth bolt

797 Series M-M/F-F Adaptor

Male-Male or Female-Female Adaptor, Globally Approved, Explosive Atmosphere Cable / Conduit Accessory

Designed to convert existing threads

General purpose / industrial version available

Supplied with male or female threads

Can be supplied with thread conversion

Equipment interface ‘O’ ring seal available on male-male

-60˚C to +200˚C

Globally marked, IECEx, ATEX & cCSAus

Can be used with 737 (not Ex d direct entry applications)

E1FU/E1FX/E1FW

Ex e, Ex d, Ex nR, Ex ta | Explosive Atmosphere Cable Gland

For all types of Armoured cables

Globally Approved, Explosive Atmosphere Cable Gland

• Metal-to-metal armour clamping

• Direct & remote installation

• Displacement type flameproof inner seal

• Controlled outer ‘load retention’ seal

• Unique OSTG prevents overtightening

• Designed to prevent Coldflow

• -60˚C to +130˚C

• Class I Zone 1, 21 and Zone 2, 22 Class I Division 2 ABCD

• Globally marked, IECEx, ATEX & cCSAus

• EMC tested

CP SERIES ALUMINIUM JUNCTION BOX

Material: Aluminium with low content of copper

IP Rating: Material IP66

Ambient temperature range: -50ºC to +60ºC

Approvals: INERIS 03ATEX0009 GOST R

Marking:

STANDARD

II 2 GD

Ex-d IIC T(*) Gb

Ex-tb IIIC T(*) Db IP66

* T6/T85°C, T5/T100°C, T4/T135°C

II 2 GD

Ex-e IIC T(*) Gb

Ex-t IIIC T(*) Db IP66

* T6/T85°C, T5/T100°C

Surface treatment: Painted by green colour polyurethane painting cycle RAL6003 (other colour available upon request)

Thread: Metric pitch 1.5, ANSI B1.20.1 NPT, UNI-6125

Standard certificate label: Made by self adhesive UV and corrosion resistant polyester, approved by INERIS Laboratory.

Accessories available upon request:

*Internal anticondensate painting

*Traffolyte/Stainless steel certificate label

*Terminals